Special machine construction by WERUCON – from concept to implementation

Be it equipment, devices, or special machines: : As a company in the manufacturing industry, you set high standards for your equipment. We are happy to develop the required equipment for you and support you throughout the entire process – from concept development to operation. Our experience is predominantly based on the optimisation and humanisation of work processes in assembly and handling technology. We convert our creativity and expertise into innovative solutions using modern CAD systems.

We manufacture and assemble entire devices and systems for our customers. The assembly systems from WERUCON are custom-made products which are fitted into the infrastructure of the client. In addition to our excellent WERUCON quality, we guarantee a high level of customer satisfaction by complying with deadlines and costs.

WERUCON: Your powerful partner

We support our customers in all project stages:

- Solution-oriented consulting and planning

- Innovative concepts

- Construction

- Turn-key plants

- Careful installation of the plant

- Re-engineering of existing plants

- Quality control throughout the project

- Service, warranty, and after-sale support

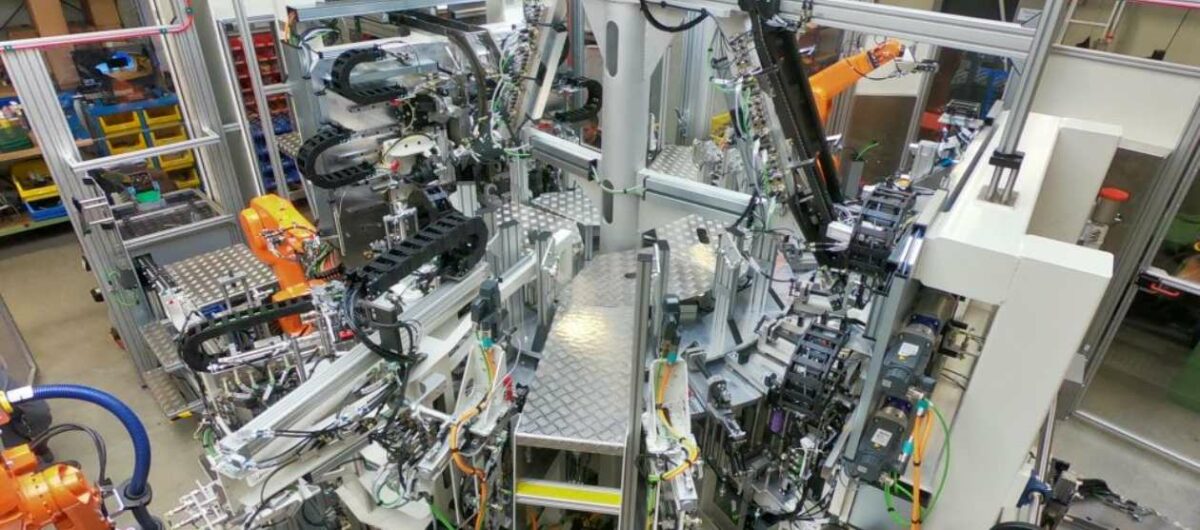

Our high level of process knowledge of the automotive industry has made us a partner for automatic assembly machines machines of renowned companies in the field. Our engineering team is formed by qualified engineers and technicians, who develop technical solutions with in-depth knowledge and many years of experience. Equipped with the latest CAD technology, we have a very extensive library of standards. This enables us to offer our customers attractively priced solutions at a high technical level. As requested, the entire project management, including development, design, manufacture, assembly, commissioning and technical documentation, is carried out according to your specifications.

For the the automation and rationalisation of production processes, we develop and build customer-specific equipment, devices and special machines.In order to meet the quality standards of our customers, production is carried out by highly qualified personnel on state-of-the-art machine tools. High-quality measuring and testing equipment guarantees a reproducible quality. Our project engineers accompany orders from the first contact to the commissioning of the plant and beyond. For us, successful project management means delivering the highest quality on time at fair prices. Our long-term customer relationships attest to our great customer satisfaction.

We have demonstrated our know-how in plant and fixture construction in many projects. Process knowledge and the will to achieve the highest quality with adherence to deadlines and customer loyalty have made us a reliable and competent partner for our customers.

Automotive and supplier industry

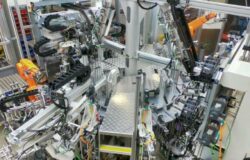

Our main focus in the automotive industry is automated assembly. Our in-depth knowledge of steering system assembly is another core field of our work. From engineering tasks to the supply and integration of assembly systems, we have proven ourselves in many projects as a partner to automotive manufacturers and supplier companies.

Plant engineering

We design and supply assembly and transfer systems for plant construction.

Consumer goods industry

For the consumer goods industry, we develop and manufacture automatic assembly machines and testing systems.

Special machine construction: customised / individual / unique products

We are your supplier of engineering services and special machines for automated assembly, e.g. in the automotive industry. We plan machines and systems for complex automated processes precisely according to your specifications.

In the field of special machine construction, we develop and produce comprehensive automation solutions as well as complete assembly systems or machining centres..

At WERUCON, we build individual machines and systems for a wide range of industries. Together with our customers, we design the desired special machine and determine the scope of services. Constructions and drawings are created using the latest CAD techniques. With WERUCON’s production plants and special machines, you receive state-of-the-art technologies that are long-lasting and efficient. Our special machines are in great demand for the optimisation and automation of production.

In addition, we offer engineering services for various branches of the manufacturing industry.

Now is the right time for an request

Special machines from WERUCON: an overview

At WERUCON, we offer you the complete range of operating equipment:

Fixtures

Examples:

Sleeve assembly

Small-series production for the automotive industry often requires simple devices and equipment when manual assembly is either impossible or impractical. For sleeve assembly of exclusive vehicle types, the wheel spindle and sleeve are placed individually in the fixture. Sophisticated lever ratios and disc cams are used to spread the sleeve and fit it onto the bearing seats via the steering spindle.

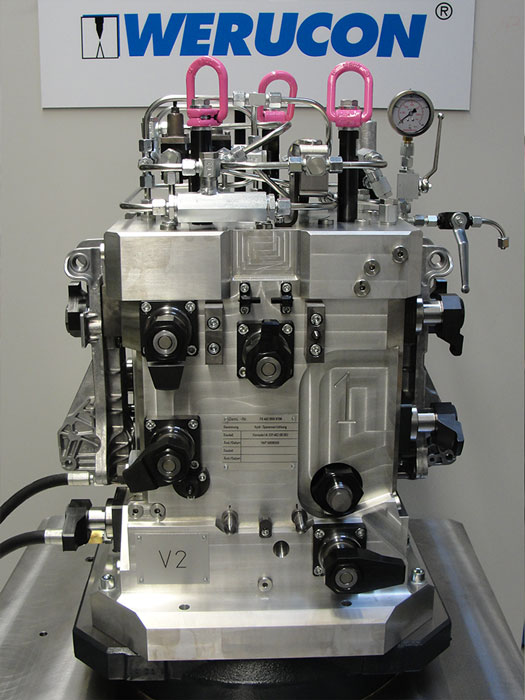

Hydraulic clamping device

For the machining of component blanks on machining centres, clamping devices are manufactured for manual loading and subsequent hydraulic fixing. Usually, only one hydraulic connection is available for several clamping points and, if necessary, a required clamping sequence. This makes the hydraulic clamping device complex in its design.

Mounting pedal cover

In the area of spare parts production, or when only small quantities are required, such as for exclusive vehicle types, devices for mounting the pedal covers on the pedals are necessary. Depending on the customer’s requirements, semi-automated fixtures can also be used in addition to purely mechanical fixtures. In this case, the components are placed manually and either the device is operated manually or the assembly process is activated via the operation of the two-hand safety switches.

Lubrication systems

Examples:

Coil lubrication

For pre-series production, a manually operated station for applying lubrication into the groove of coils was created. The device was designed to be integrated into series production at a later stage. For this, only the hand lever mechanism had to be replaced by a pneumatic cylinder. Nowadays, the coils move to the greasing position on workpiece carriers instead of the component holder.

Lubrication of bearing washers

Bearing washers also have to be greased precisely and with repeat accuracy. Different bearing sealing washers can be provided with the correct amount of grease in a repeatable manner by setting up the corresponding fixture in a device. The product selection and the coded receptacle ensure that the intended amount of grease can be applied to the corresponding component. The bearing sealing washer is fitted manually. After pressing the start button, the lubricant is applied. The bearing sealing washer can then be removed.

Lubrication of the subframe bearing

A lubricant must be applied before joining the bearings to the beam axle. After a robot has placed the bearing on the component fixture, a rotary indexing table moves the component into the machining position. The wetting device, including the protective housing, is moved over the component before the spray valve applies the lubricant to the circumference of the chassis bearing in a 360° circle.

Semi-automatic systems

Examples:

Universal joint assembly

WERUCON supplies semi-automatic assembly lines for the production of universal joints with an automated drawn cup needle roller feeder from magazine-loaded blisters. For the positioning of the components to be assembled, specific interchangeable fixtures are created. Thus, a semi-automatic assembly line can be used for various component variants, e.g. for spare parts production. The assembly process takes place automatically after the start button is activated.

WERUCON also supplies fully automatic universal joint assembly systems.

Assembly of steering spindle damping element

A multipart steering spindle including damping element is manufactured with 5 semi-automatic stations. The processes of the stations are:

- Embossing groove (latching damping element)

- Pressing on damping element

- Testing of pull-off force

- Pressing on joint fork and

- Flanging after insertion of the cover plate

These sub-processes were also implemented in a fully automated system.

Assembly of wishbones/axle components

For smaller series and for the production of spare parts, semi-automatic plants are used for the production of axle components. For this purpose, WERUCON supplies lines with screwing processes, stations for joining bearing bushes with press-out functions, flanging devices and more. The scope of supply also includes ergonomic component supply by means of load carrier tilting devices with height adjustment, as well as electrically operated component transport trolleys.

Mounting exhaust manifold insulation

To protect sensitive components in the compact engine compartment, exhaust manifolds are surrounded by insulation. The insulations consist of two-part sheet metal shells which are equipped with heat-resistant insulating material. In the semi-automatic assembly lines, the exhaust manifolds and the insulation half-shells are positioned manually, and then a finished component is removed. After the insulation has been assembled, a mica gasket is applied with adhesive and inserted into the connecting flange, the manifold is cleaned with compressed air and suction equipment, and finally a laser inscription including a data matrix code is applied. Optionally, the finished components are fed directly from the assembly line to the packaging by means of a conveyor belt.

Calibrating sliding seats

For gap reduction, the sliding seats of steel moulded parts are calibrated and subsequently the flow rate as well as the displacement force are determined. In WERUCON systems, the component is inserted manually, while the rest of the process runs automatically. In the calibration systems, different, component-specific fixtures are located on a servo rotary indexing table. Depending on the selected component type, the corresponding fixture is made available for placement and then automatically calibrated.

Leak test and assembly of exhaust manifold sealing ring

After manual component entry, the automatic leak test is carried out and then a sealing ring is automatically fitted in the flange of the exhaust manifold. Before this, the sealing ring is separated from a magazine, picked up by the robot and fed to an adhesive applicator. Good parts are then automatically marked.

Clamping presses for air springs

The semi-automatic WERUCON clamping presses for air springs are equipped with quick-change tool changing systems and workpiece carrier changing systems to accommodate different component variants. The adjustability of the interchangeable tools enables exact results in roundness to guarantee the tightness of the connection joint of the finished component.

Fully automatic systems

Examples:

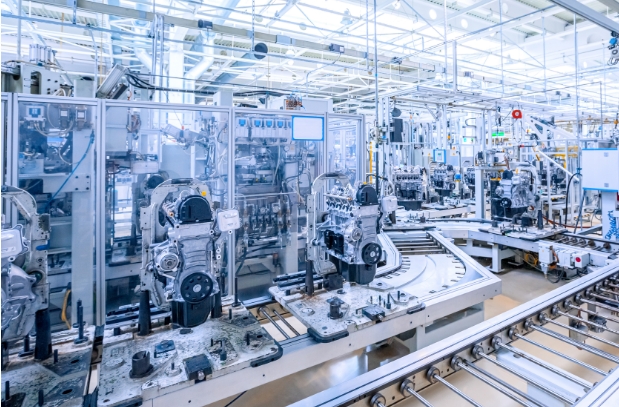

Universal joint assembly

WERUCON supplies fully automatic assembly systems for the production of universal joints. The components are supplied to the fully automatic handling and assembly by robots via feed systems with sufficient storage capacity, for a large plant autonomy. After the individual joining processes, the bending moments at the joint are calculated. This makes it possible to correlate the bearing pairs of a component. The finished components are placed in customer load carriers by robots. For this purpose, WERUCON has developed a rotary station with three load carrier positions and handling for deep-drawing foils (blisters). The entire system achieves a cycle time of 8.5 seconds per component.

Assembly of steering spindle damping element

For the production of a multipart steering spindle including a damping element, WERUCON has developed a fully automated machine which is supplied with component holding trays via feed belts. The trays are manually loaded with the components at height-adjustable workstations. Removal of the components and further handling is carried out by means of robots, which are arranged in a suspended position. The processes of embossing the groove (latching the damping element), pressing on the damping element, testing the pull-off force and pressing on the joint fork are carried out at the rotary indexing table. After mounting the cover plate, flanging is performed alternately in two stations to optimise the cycle time. The finished component is fed for further processing via a workpiece carrier conveyor belt. WERUCON has also created semi-automatic systems for the individual processes.

Front-end carrier machining centre

After manually feeding the component onto a clocked feed belt, the fully automatic machining of the front-end carrier is executed with the following processes in a cycle time of 30 seconds per component:

- Transfer of the component from the transport system

- Alignment with plastic features of the component

- Floating gripping on aluminium tube contour

- Fixing of the floating grippers

- Drilling of 3 holes ø 10.1 mm, where the holes must be drilled from both sides of the tube (avoidance of chips in the tube); extraction of chips; minimum quantity of lubrication

- Chipless cutting of the tube on both sides with discharge of the cuttings

- 180° rotation of the component holder (suspended rotary table above machining units)

- 90° swivelling of the component for vertical drilling

- Automatic feeding of three rivet nuts (feeding system, separation, handling)

- Pilot drilling Joining of the three rivet nuts Hydraulic riveting processes

- Punching of two holes at tube ends for thick sheet metal nuts with waste removal

- Automatic feeding and separation of the two thick sheet metal nuts

- Setting of the thick sheet metal nuts caulking of the thick sheet metal nuts

- 90° swivelling back transfer by handling

- Generation of label and automatic application to front-end carrier

- Discharge of the finished I.O. component

- Transfer of N.i.O. component to storage compartment

Pre-assembly of clamping parts

WERUCON developed a fully automatic machine for the pre-assembly of clamping parts for mechanically adjustable steering columns. The components are fed via bunkers in spiral feeders over linear rails for separation. Pick-and-place handling brings the clamped parts to a servo rotary indexing table, where the other components are joined. Assembly is partly carried out by a robot. Another robot removes the various finished clamp parts and places them in the appropriate container in the load carrier station.

Further WERUCON services

We are experts for special machines in the field of assembly technology, as well as a leading company in the field of state-of-the-art dosing technology for liquid and semi-liquid lubricants. The dosing technology for liquid substances is used in metal cutting and non-cutting metal processing and ensures process-reliable and precise lubrication. Semi-liquid lubricants such as greases are dosed using our dosing technology in a reproducible manner, mainly in assembly technology.

DO YOU HAVE QUESTIONS?

One of our sales representatives will be happy to provide you with competent advice.

WERUCON GmbH

28309 Bremen